Product intrduction

KALESON QW-150 Lseries is a large upper and lower bucket separation industrial vacuum cleaner with external compressed air pulse back blowing. It is mainly used in environments with large amounts of dust and continuous work, as well as in conjunction with automation equipment to achieve online linkage automation products. It can work continuously for 24 hours without stopping, and the machine automatically cleans the filter element to achieve the purpose of suction without attenuation. It is suitable for working conditions such as steel mills, power plants, cement, casting, machining, semiconductors, precision machinery, chemical metallurgy, etc.

Product image

Product parameter

Product parameter | |||

Model | QW7-150L | QW9-150L | QW11-150L |

Volts | 380/50V/Hz | 380/50V/Hz | 380/50V/Hz |

Power | 7.5 Kw | 9Kw | 11.0 Kw |

Vacuum | 34Kpa | 29Kpa | 32Kpa |

Airflow | 540M³/h | 850 | 1050 |

Cleaning method | Pulse blowback | Pulse blowback | Pulse blowback |

Air source | External compressed air | External compressed air | External compressed air |

Filter area | 120000C㎡ | 120000C㎡ | 120000C㎡ |

Noise | 74Db(a) | 76Db(a) | 77Db(a) |

Caliber | 50-76mm | 50-76mm | 50-76mm |

Dustbin | 150L | 150L | 150L |

Weight | 185kg | 205kg | 226kg |

Dimensions | 1260*780*1850mm | ||

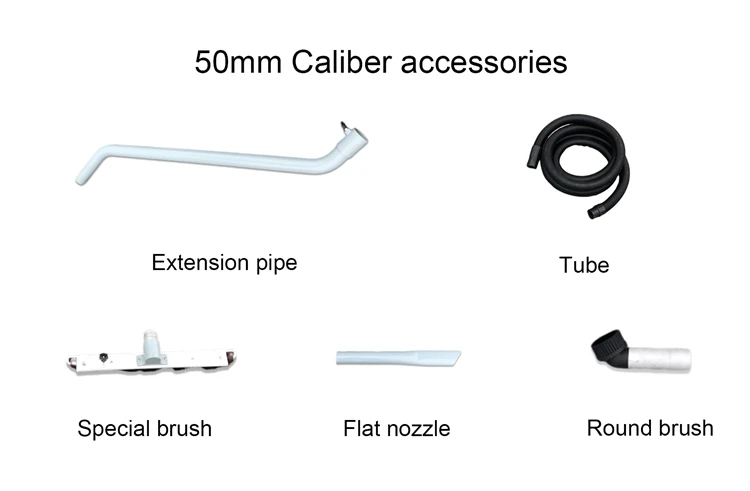

product accessories

Product features

1. The entire product is made of carbon steel spray coated and thickened stainless steel material, which is sturdy and durable.

2. The power source adopts high-quality domestic air ring high-pressure fans with strong suction power

3. The electrical control section and electrical components use branded electrical components

4. The filtering device is made of non-woven film substrate processed into HEPA high-efficiency filter, with an accuracy of up to 3 microns

5. The vacuum cleaner adopts cast aluminum processing technology, which is sturdy, durable, and quick to install.

6. The vacuum cleaner adopts a separate collection bucket design with upper and lower buckets, which is flexible and convenient for dumping dust

7. The dust cleaning method adopts pulse back blowing to clean the dust and ensure the real-time permeability of the filter element filtration.

8. Mobile casters, using high-quality polyurethane load-bearing silent casters, comfortable walking, long service life